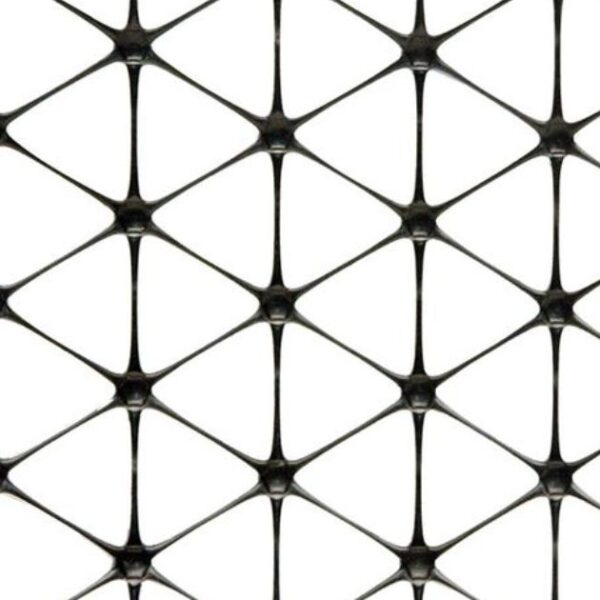

TRIAXIAL GEOGRID

The Triaxial Geogrid is an advanced geogrid is specially designed to hold your aggregate securely in position and can work effectively in heavy-duty environments. Its hexagonal grid contains triangular holes to add strength and durability.

Different to biaxial geogrid, triaxial geogrid offers strength in three directions instead of two, allowing for more uniform stress distribution across the geogrid. The triaxial structure is particularly effective in applications where multi-directional stresses occur, such as in base reinforcement for roads and railways, and in large area stabilisation projects. The isotropic nature of the triaxial geogrid means it can better accommodate stresses from various directions, providing improved performance in certain soil reinforcement scenarios.

Made from polypropylene, this geogrid has been punched and stretched into a hexagonal pattern to provide a stabilising layer to a substrate. With this geogrid, you can enhance the bearing capacity of your project, minimise the excavation needed on site, and control the settlement of aggregate, keeping it all in the appropriate position for longer.

Geogrids are perfect for a wide range of applications, including pavement optimisation, subgrade stabilisation, and soft soil capping. It is also ideal for long-term loading applications, such as void spanning, reinforced soil walls and slopes, load transfer platforms, basal embankment reinforcement, and veneer stability. Can be used with non woven geotextile membranes to provide excellent separation, stabilisation and also drainage of surface water.

This triaxial geogrid is designed to provide high load absorption and distribution, thanks to its hexagonal structure with triangular apertures. It also features a stiff structure, high rib profile, and strong junctions for optimum aggregate interlocking and confinement. With its advanced durable material, Triaxial Geogrid is perfect for improving roads, rail, and trafficked areas.

Triaxial Geogrid is available in a variety of sizes. It is easy to handle and simple to install, with subsequent time and cost savings. Plus, it has a diminished carbon footprint and improved sustainability, making it an eco-friendly choice for your project.

WHY CHOOSE MULTIAXIAL GEOGRID?

- Reduces granular layer thickness and CO2 emissions in construction by up to 50%

- Improves bearing capacity on railway projects and stabilises the rail ballast and track bed to limit the movement and displacement of the rail ballast, leading to a reduction in maintenance

- Cost savings in foundation material required to build working platforms by up to 50%

- Durable structure that provides greater stability and stiffness in challenging weather and environmental conditions

- Multiple layers form a stiff beam that spreads heavy loads over a larger area, reducing differential settlement

- Can be installed quickly, reducing construction costs when building all pavement types over soft ground for standard and heavy vehicle loads

- Proven laboratory and field calibrated design method