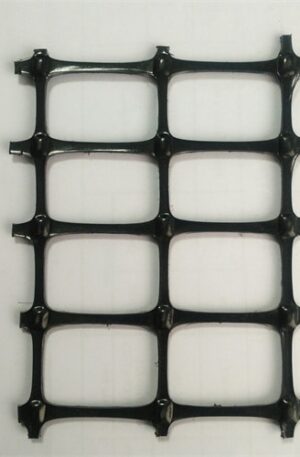

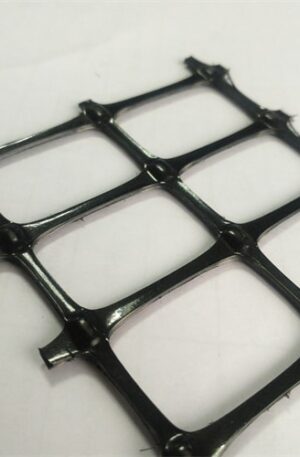

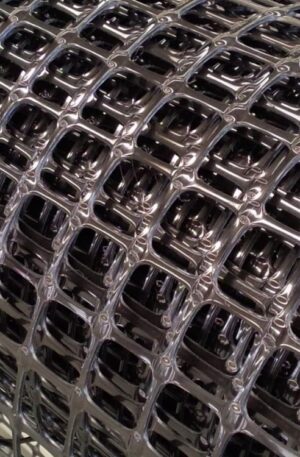

PP geogrid or Polypropylene geogrid is a high-strength geosynthetic material made from extruded polypropylene, typically punched and stretched to create a square/rectangular, biaxial, or uniaxial grid. It is primarily used for soil reinforcement, stabilization, and load distribution in roadbeds, embankments, and retaining walls due to its, high tensile strength, chemical inertness, and durability.

Key Characteristics and Benefits for PP biaxial geogrids

High Strength & Stability: Provides high tensile strength in both longitudinal and transverse directions, improving bearing capacity of foundations.

-

- Durability: Resistant to chemical, biological, and corrosive environments.

- Cost-Effective: Reduces the need for, and thickness of, structural fill, saving on construction costs.

- Applications: Commonly used for soil reinforcement in road construction, subbase stabilization, railroad beds, and retaining walls.

- Easy Installation: Lightweight and easy to handle, reducing installation time and labor costs.

Common Specifications of PP Geogrids

-

- Material: 100% Polypropylene (PP).

- Structure: Biaxial (square aperture) or Uniaxial (longitudinal oriented).

- Tensile Strength: Common strengths range from 20–20 kN/m to 50–50 kN/m

PP geogrids are highly effective in managing soil movement and increasing the load-bearing capacity of weak soils.